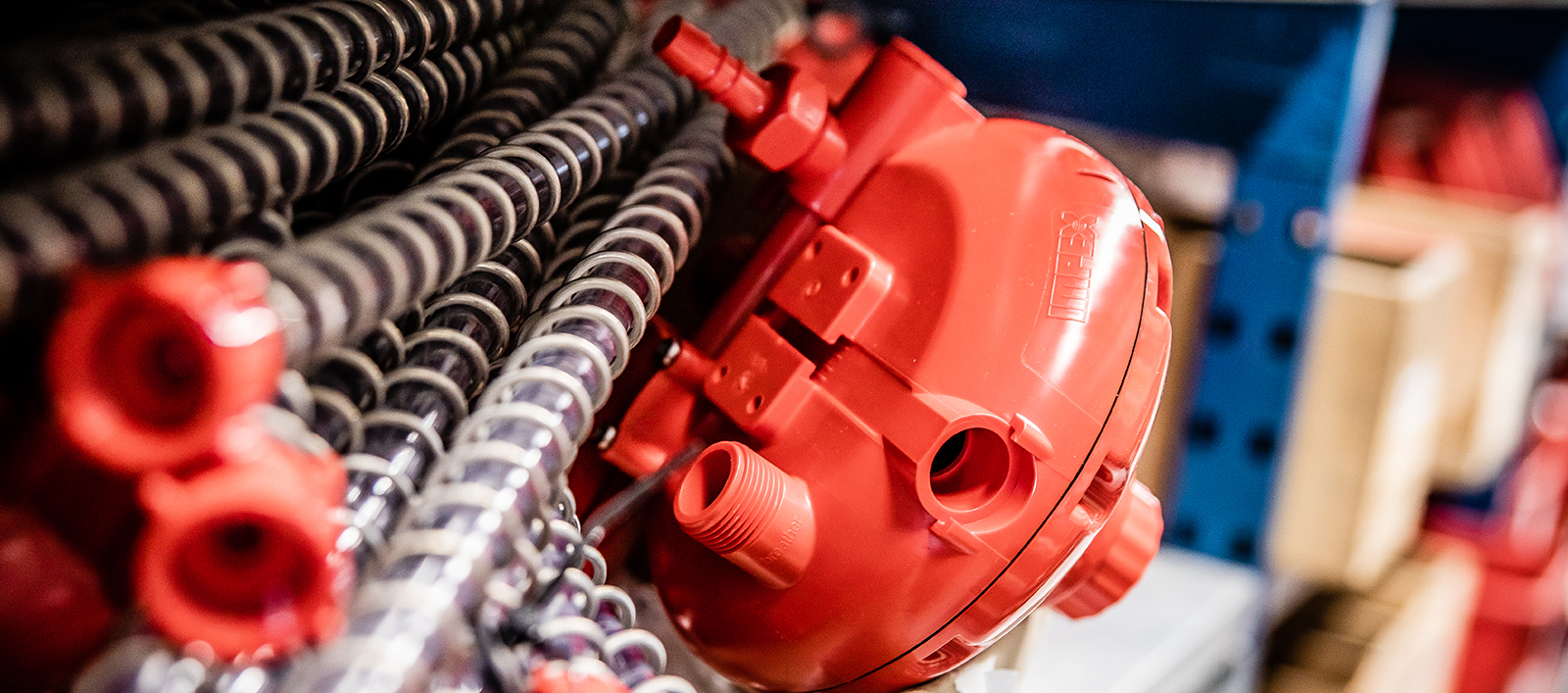

With an automatic flushing system, your chickens are always assured of fresh and cool drinking water. It also allows you to keep the quality of the water in your drinking system at a high level. The Impex I-Flush is a completely automatic flushing system for poultry drinking water lines.

An intelligent flush computer forms the heart of the I-Flush automatic flushing system. First, the flushing computer signals the pressure regulators on the drinking lines, based on pre-programmed flushing schedules or information from sensors in the drinking line. Next, the water travels under high pressure through the drinking lines. The water is then drained through a drainage hose, which connects the end air outlet set to the main drain. You can also connect a water detection system onto the end air outlet set. This system will emit an alert when there is no water in the drinking line.

Three ways to automatically flush

Three ways to automatically flushThe I-Control flush computer has a touchscreen control panel that you can use to manage the settings of the flushing system. For example, you can create automatic flushing schedules per line, for all lines, or set maximum parameters for the temperature and biofilm sensors. You can also configure the duration of the flushing programs, interrupt flushing programs, or select a maximum number of flushing programs a day.

|

Optimum production results |

|

|

Savings in labor and water costs |

|

|

Reducing medication use |

In 2011, Raymond Veldhuizen started keeping 24,000 organic laying hens. In 2018 he exchanged his old drinking system for an Impex drinking system with I-Flex 14-SP drinking nipples and drip cups. We visited him at his farm in Maarsbergen to talk about his experiences with our system.

After a lightning strike caused a fire in the two brand new poultry houses of Beek Poultry in Barneveld (the Netherlands), Impex dealer Beek Agri equipped the houses again in 2021. The laying hens are now kept according to the 3 Star Better Life quality mark (most profound Dutch quality mark). Henk van de Hoef of Beek Agri explains it all.

Water quality & hygiene

Water quality & hygiene  Drinking water systems

Drinking water systems  Pig drinking water solutions

Pig drinking water solutions